MODEL 15 TELETYPE RESTORATIONS

The Vintage Computer Festival West exhibit I am committed to involves both my working ASR 33 and a model 15. The most critical work left to meet the deadline is to get at least one model 15 restored to good operation in time for the show.

We have three model 15 systems under restoration - mine, Marc's model 19, and Marc's model 15. Marc is focused on keyboard restoration for his model 19 and finished it up today. His other model 15 had some keyboard issues which we corrected. I focused on the printer unit of my model 15, which had a mostly frozen main shaft.

Marc's keyboard has a tape perforator and a column counter attached. He noticed that he could punch tape when the keyboard was switched to the "keyboard only" or "keyboard plus tape" setting, but when on "tape only" it failed to punch. Also, his counter was not working.

Dirty contacts and a misadjusted switch were the primary cause of the problems he experienced and were quickly corrected. Once the punch and counter were working exactly as they should, he turned to a strange taped up set of wires.

He realized that a filter had previously been wired to the punch solenoid to absorb voltage spikes as the magnet switched off. Using some handy components from his workbench, he installed an equivalent filter circuity.

Ken spent time with Marc's model 15, figuring out the wiring since it doesn't match any schematics we have. He sorted out the keyboard connectivity and behavior, but the printer unit needs work. It doesn't reliably print what we send to it, which may be a consequence of an unadjusted motor. This unit has a motor with a governor, which must be set to the right speed to operate at 45.5 baud. We also found the print mechanism to be a bit goopy and sticky.

I focused on the printer unit of my model 15. When I arrived, the main shaft that runs from the motor and powers the keyboard as well as all the functions of the printer, was almost frozen solid. It could only be moved a few degrees back and forth.

My first task was to apply new oil to the oiler caps and to the felt washers that lubricate the various clutches on the main shaft. The shaft should turn continuously, with a number of clutches that are tripped to complete one rotation before coming to a stop. The clutches were for print/function cycle, spacing/carrier return, and the selector that decodes the incoming bit stream.

After about 90 minutes of working everything, I had the shaft rotating and the clutches rotating until tripped. I put the printer on the body and fired up the motor. The shaft rotated away, the keyboard worked well, but the printer had some issue.

The selector mechanism, which converts incoming serial characters into a parallel arrangement of code bars, was continually operating even when I held the selector magnet armature to the MARK position. It should finish the current cycle and stop the clutch until the next SPACE arrives which is interpreted as the start bit of the next character.

I disassembled the mechanism and found the clutch trigger and stop levers to be frozen with sludge. After about 30 minutes with light clock oil and careful exercising of the parts, I had it working properly. When held in MARK position, the clutch stays stopped. A SPACE condition triggers one rotation of the selector mechanism.

The other issue with the printer was that the carriage was moving steadily towards the right margin - continuous spacing. Working on this took the majority of the day. The spacing mechanism involves a clutch about dead in the middle of the shaft. Its trigger and stop levers were frozen in place.

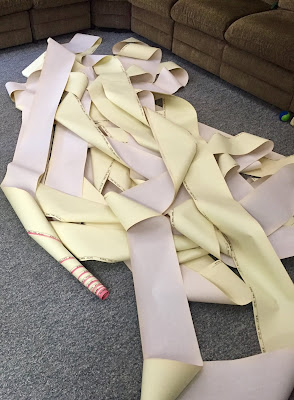

Even with lots of clock oil and work, I didn't get the levers moving any better. I might have to do a more major disassembly of the printer to free this up. In preparation for that, I removed the carrier from the rest of the printer. The carrier has the typebars that swing up to print the characters, plus the ribbon mechanisms.

We put the carrier into a bath of Simple Green and will leave it for two days, after which I will dry it and oil it to make sure the typebars move smoothly and rapidly. I can't just dunk the rest of the printer in the bath because there are some parts such as the selector magnet that shouldn't be put in the cleaner. If I disassemble more, those pieces can be cleaned by the same method.

Quite a bit of the printer is also hampered by dried lubricants. There is a function mechanism that rotates forward to operate any function lever whose slots exactly match the settings of the five code bars. For example, if the code bars select a carrier return, then the function lever that matches the code drops forward and when the function mechanism rocks, it drives the levers to trigger a carrier return.

The function mechanism was not moving to its full range and was very hard to move. I worked it for a while and improved it quite a bit but more is needed. The function mechanism has to release the code bars in order for the selector mechanism to set them up with the incoming character code. Right now that doesn't work.

One of the function levers is the 'space' character, which should trigger the space clutch to take one rotation and move the carrier over by one column. Since it is not reliably triggering or stopping, it either moves steadily rightward or doesn't move at all.

The other thing that should happen is a print cycle, if it is a printable character set up on the code bars. That didn't happen at all, probably due to the stiffness of the function mechanism.

Basically, all the parts are on the printer and not rusted, but it will take quite a bit of work to get everything moving properly. The odds are high that I will have to disassemble it further to get it clean enough.

MODIFYING SBC 6120 (PDP8 CLONE) TO RUN AT 110 BAUD

I built the Single Board Computer 6120, which is a PDP-8 replica. Intersil designed a microprocessor that was a copy of the PDP-8, used for a while by DEC to build products such as the DECMATE, the 6120. This board is built around the 6120 processor, supporting a front panel that mirrors the panel of a PDP8 although it is scaled down in size a bit.

The board has jumpers to set the speed of the serial port, allowing four options with the slowest at 300baud. The ASR 33 needs to run at 110 baud. I looked at what might be possible to interface this computer to the teletype.

I had discovered that the serial port is driven by a TTL oscillator chip to drive the baud generator, separate from the clock that drives the rest of the circuitry. Therefore, if I can slow down the baud generator by the ratio of 110/300, it would make the slow jumper actually operate at 110 baud.

|

| Main oscillator at 5MHz and serial port oscillator at 4.9152MHz |

The original oscillator was 4.9152MHz and I was able to find a compatible TTL oscillator that runs at 1.8432MHz thus the effective baud rate is 111.7, close enough to work perfectly.

|

| New oscillator chip at 1.8432MHz makes 300 baud = 111.7 baud |