Today was more of a mechanical day - dealing with physical mechanisms, solidified lubrication, age related changes in materials, and similar fun. I did get a bit of electronics in, while testing out a possible change to the SLT to CMOS 3.3V signal receiver/driver circuits I build to interface between the 1130 and the fpga board.

1132 PRINTER RESTORATION

I began taking the printer apart to find the sticky or frozen parts gummed up by old grease, in order to clean them, reoil and get them working properly. I did confirm the condition I expected, rotating parts that don't, and began the slow process of returning them to easy movement.

The printer components that result in a character printing start with a solenoid that pivots a downward rod. That rod slides a long horizontal bar backwards, whose far end has a hook. The hook pulls on a pivoting lever that reachs up to the cam clutch for the line position. The cam clutch has a lever that holds a dog on the rotating cam so that it's teeth are raised away from the rotating cam shaft inside.

When the pivoting lever is rotated by the action begun at the solenoid, this lever lets the dog on the cam fall free, thus its tooth engages in the cam shaft. The cam begins to rotate with the shaft it has just latched to. The cam has a high point that will push the print wheel hanger forward, then later will pivot a restoring latch which forces the pivoting latch to again hold the cam dog. There is a spring loaded detent lever as well, which pops into a notch on the edge of the cam to hold it in the 'idle' position.

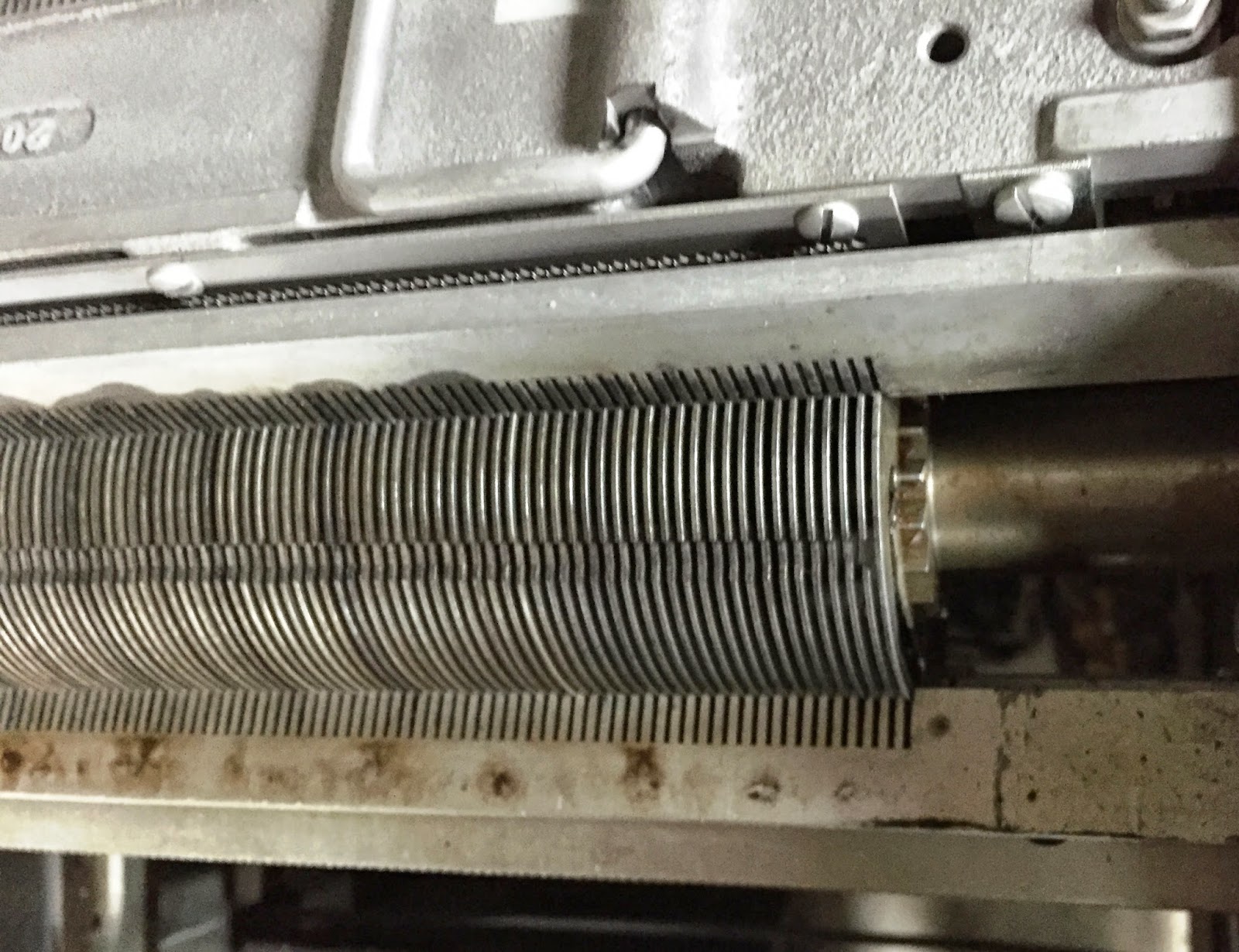

120 wheels are rotating by a gear driven from the printer motor. These wheels hang from a pivot point, allowing them to be forced forward closer to the paper on the platen. As the wheel moves forward, that motion is opposite to the turning direction from the drive gear, thus temporarily the print wheel appears to stop rotating just as the typeface slams into the ribbon and paper behind it. The wheel restores to its rest position by the force of gravity once it has bounced off the paper.

I removed the magnet assembly that holds the 120 print position solenoids, the actuating lever, the long horizontal bar and the pivoting latch. This fits up against the cams, restoring lever, detent lever and further forward, the print wheels on their pivots, but I removed the magnet assembly to work on all the parts methodically.

The pivoting latches were the first component I checked. Most of the print positions at the right side of a printed page were moving freely, but quite a few of the first 60 were frozen or very stiff. The worst of the latches were in the first 15 print columns, exactly where my test program attempted to print a known line. No wonder there was no detectable impression in most of the columns.

I used some Mobil 1 synthetic oil to flood the pivots and work all the pivoting latches, hoping to get them moving easily. After half a hour of oiling and hand movement, I had just a few, less than eight, that were still noticeably stiff. The other 112 were moving fine. I verified that my pushing on the downward rod just where the solenoid magnet will pull it - seeing that the pivoting latches were moving properly and easily as I did this.

I will take some more time for the oil to seep into the remaining eight pivot positions - they all move but with resistance and stick in the position they have when force is removed. The restoring spring that should pull them back to rest position can't overcome the high drag of the glue-like old lubrication and possibly a bit of rust. I will come back to these tomorrow and on subsequent days until they are all moving well.

I tried some of the cams, restoring levers and detent latches by hand, finding that these also were a mix of easily moving and frozen units. I will have to oil and manipulate the pivot points of these as well. I hope the dog mounted on the rotating cam is moving adequately, because if I need to work on those, I will have to take apart the entire set of cams from their shaft and rod. If the dogs work okay, then I won't need to do any disassembly.

The last area to inspect is the print wheel pivots, to test whether the print wheels can move forward if pushed by the print cam. I will look at this later when I begin oiling the restoring latch and cams.

My first look at the restoring latches shows major sludge drag and stickiness. This is going to be a long process to rehabilitate the printer, but I am confident I will eventually have it running well.

1442 CARD READER/PUNCH RESTORATION

I completed reassembly and some adjustments of the 1442. It continues to cause two kinds of problems - read checks on some cards and failure to slide fully into the cornerering station. The latter problem is just too much drag, as far as I can tell, since all the rollers and clamps are working properly. Further, it occurs even with the top cover of the station open, showing that it is drag on the face of the card against the brushed aluminum pathway.

I have cleaned, polished and cleaned these over and over. There is a possibility that it is drag with the punch station plate, since there is a bit of the metal base that can't be reached for cleaning due to a plate atop it that forms a narrow throat for card exit from the punch to the cornering station. I will take this apart, clean it more, and then adjust the throat upon assembly.

The read checks might be marginal light levels with the lamp, something that I can check out and adjust later. One annoying problem is that the individual condition lights that tell you what kind of Check has occurred are implemented with those miserable bare wire lamps hooked to the SCR, just like the main panel of the 1130. This means they break as you replace other bulbs, are touchy and darned hard to get an entire panel of them operating.

I did manage to get the Hopper Check lamp to work, but whatever is occurring to raise a check when I boot a card, is for one of the lamps that is NOT yet lighting. It would be helpful to know exactly what the reader believes is wrong.

SAC INTERFACE FOR ADDING PERIPHERALS TO THE 1130

I decided to put a 10000 pf capacitor across the base resistor between the 1130 SAC signal coming in and the transistor that will be switched, as a means of more rapidly removing the depletion charge and getting a faster shutoff of the otherwise saturated transistor. Without the capacitor in the circuit, I was seeing about 240ns delay between the drop of the incoming signal from the 1130 and when my transistor cut off and raised an pulse going out to the fpga. When I added the capacitor, my delay shrank to about 60 ns, which is quite acceptable in a 450 nanosecond cycle.

However, I see a phantom pulse rising about half 225 nanoseconds before the real one. Nothing on the incoming signal seems to match when it happens, thus this needs some additional study to determine why it occurs. It might be an induced signal from another nearby circuit switching, or caused by power rail or ground bounce. If it is the latter, I can add some more capacitors on the board to buffer power nearby each circuit.

I am going to think about this for a while, figure out some tests to confirm the cause, and then run tests until I am sure of the cause. The pulse is short, so I could filter in out in the fpga if necessary but that would add extra delay before I could recognize the logical condition mapped by the signal. Since I worked to remove delay, I don't want to be adding it back.

DATACENTER SHED CONSTRUCTION

The electrical system inside the shed is closed up, lacking only the connection to the overhead lighting I have yet to build and install. I took my multimeter out and verified the wiring including lack of shorts. Everything looks good in the wiring, Just need to anchor the panel, route and anchor the utility outlets, and anchor the light outlet.

Tonight I will tap the holes on another 7000 lumen 100W LED lamp array, putting the LED unit on heatsinks, adding a focusing lens and fan, then wiring to a constant current power supply which converts the 120V line power to a bit over 3A of DC current, which floats to somewhere over 30V due to the cumulative voltage drop of the LEDs in the array. I may be okay with a single lamp for the entire shed, but I can also use them in my family room to provide strong bounce lighting off the whitewashed cathedral ceiling.