While doing my studies on the spacing mechanisms, I came across a diagram giving me adjustment advice for the contact bails that touch the microswitches for carrier return and tab operations. These block issuance of new print commands until the variable duration events (return and tab) have completed. I think they are adjusted properly but I can fine tune this once I am able to run the printer from diagnostic programs and watch on a scope.

|

| Adjustment instructons for contact bails and microswitch levers |

It was hard to track down because it didn't fail when I hand cycled (rotated the mechanism by hand with a wheel crank) slowly, watching all the moving parts. It will sporadically take a few extra cycles if I spin the wheel crank rapidly. Under powered movement, it never stops repeating.

The mechanism is complex, triggered by three different sets of components. The button I push will cause a keylever to move down, just as it would if this Selectric had a keyboard, triggering the interposer to snap back and activate a cycle. When a character is printed by the type mechanism, a shaft rotates a cam that causes a single space to occur. Finally, a solenoid can be activated by program control to trip the interposer, causing a space cycle.

Both the solenoid and the button cause the stuttering perpetual spacing, but the print cycle cam does not. Since this worked when the 1130 was last in service, I thought that the adjustments must be okay. This had to be gummed up lubricant but I believed I had found, oiled and worked free every possible moving point.

Finally, I noticed that sometimes the space keylever was touching the interposer while the other functions had a slight space between their levers and interposers. Looking very closely at the keylever, I saw a small pivot which couples the arc of the keypress motion to the interposer at that contact point. I tried flexing those pivots, which seemed to be working okay.

The keylever with its pivoted actuator lever slides through a notch in a cylindrical stud that aligns its movement. The stud for the space function looked to be bent slightly to the left and downward compared to the others. When I operated the keypress elements separately, I discovered that the actuator was binding or grinding on gritty sludge in the slot, made worse by the bent and twist of the stud.

|

| Keylevers sliding in slot of cylindrical studs, triggering interposers at bottom |

|

| Bent, twisted and gummed up slot for the space keylever, before repair |

After hooking it up, I began issuing commands to it from the 1130. It was a touch sticky for the first few characters but then began reliably selecting the proper characters. Interspersing upper and lower case proved out its shifting function, rotating the typeball 180 degrees to select characters from the lower or upper case side.

The red and black ribbon shift commands worked properly, although since I had an all black ribbon installed I couldn't verify that it was typing through the intended half of the ribbon. Spaces and carrier returns worked properly, but not the line feed, tab or backspace operations, initially

After a bit more work with the printer, it was typing every character correctly in both cases and executing all the functions. Sometimes, the line feed (index) operation would stick on, which tells me I have a bit more oiling and cleaning to do in that area.

|

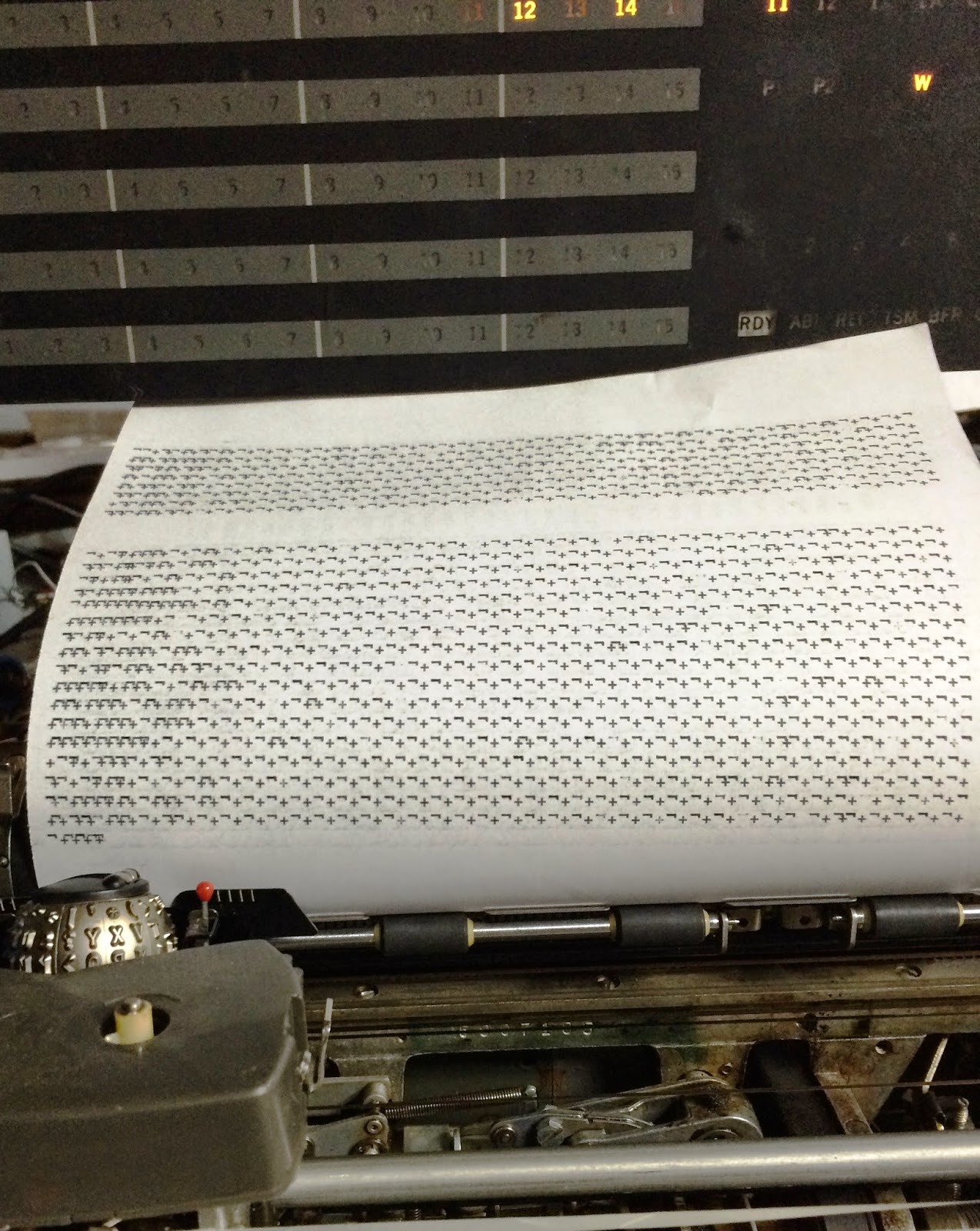

| Printing character pair at full speed to test spacing accuracy |

Video of console printer while exercising the print escapement

1131 DISK DRIVE RESTORATION

I decided to use an LM7812 voltage regulator chip on a heat sink to drop the 48V from the disk drive down to the 12V used by the time delay board. This will pull 1.25W while timing and 2.5W while the drive is running. The parts are ordered and should be here midweek.

NEW KEYPUNCH INTERFACE DEVELOPMENT

I completed more of the parsing and verification code that will run in the Arduino. Overall the code is about 20% complete but soon will be sufficient to begin testing in parallel with further development.

No comments:

Post a Comment