Ken Shirriff and I have been testing the two Raytheon built boxes that provide the Core Rope functionality for the AGC. We have been using some pulse generators and power supplies to send in the signals that will come from the AGC as it attempts to read a word of core rope memory.

|

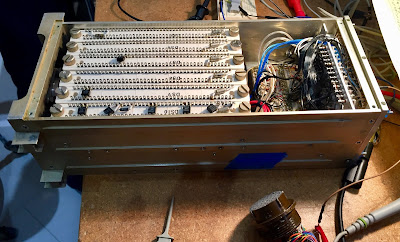

| One of the two core rope simulator boxes; Dipsticks on left, cordwood modules on right |

The early testing of the input side, where we introduced the various address bits and control signals coming from the AGC, went well. All our address, module and strand selection signals, plus the set and reset control signals, were properly detected in the simulator boxes.

We then focused on the outputs from the simulator boxes to the AGC - 16 differential signal pairs representing the 15 data and 1 parity bits of the word that was being read. The last data bit, number 16 as the AGC numbers memory bits, did not produce a good pattern.

The signal from the AGC requesting to read some address is a 1 microsecond pulse. If the differential data coming from the external system over the 85 pin connector is a binary 1, then the pulse from the AGC causes a pulse in a transformer for that bit position. The other side of the transformer produces a 500 millivolt differential signal, one side of the winding going negative while the other side goes positive.

What we saw on the 15 working bit transformers was such a differential signal, but the failing transformer showed us zero volts on one lead and a much larger positive voltage on the other lead. It still added up to 500 mv, but it wasn't swinging the two leads in opposite directions like the other transformers.

|

| Blue and green signals are not moving in opposite directions |

Cordwood stacks components between two end plates, with the parts fitting perpendicular to the plates. This allows resistors, capacitors, transistors, transformers and other parts to be fit very close together, like bottles of soda sitting in a carton, with a plate at the bottom and top of the bottles. Wires connect the parts only on the outside, along the two end plates.

While the end plates we could see were made of nylon, with the wires from a transformer routed out of the hole in one end plate and connected to resistors or other parts, for heat dissipation reasons, the transformers are actually set in drilled holes in an aluminum body that is only covered on the ends with nylon.

Thus, we realized that the lead from the failing transformer was stretched taut in its connection from transformer to its associated resistor in the adjacent cordwood module. Somehow, we thought, the insulation has rubbed on the edge of the aluminum body and caused a short.

Ken tested the short while I manipulated the transformer lead with a toothpick. Immediately, the short went away! Our permanent fix will be to glue a small bit of insulating plastic under the lead to keep it from rubbing against the aluminum body.

Now that we had proven that all the inputs and outputs between the AGC and core rope simulator modules worked correctly, it was time to test the interior logic. That is some timing and control circuits, the conversion of module, strand and core to linear addresses, and the interaction over the thick cables with Ken's external system.

We began setting up conditions and testing the parts of the linear address generation, but soon found another problem. The generated signal for an even numbered strand worked properly for 5 of the 6 even values, but strand 10 did not work.

There are some diodes and a transformer involved in this process, so we began checking continuity and diode voltage drops. The diodes and wires were fine, but the transformer output was not operating. Again, we did some testing and a lot of thinking. Finally, we began looking at the wiring from the transformer, wondering if we had another short.

|

| One of these orange transformer wires has a failed weld at the left resistor post |

When they are checked out, Ken can test his external system and its interaction with the core rope simulator boxes. The final test will have to wait until Jimmie comes to visit with the AGC and we can test the entire system - AGC, core rope simulator boxes and Ken's external system - and get it all working properly.

Recap of Core Rope Simulator function

The Apollo Guidance Computer (AGC) uses Core Rope Modules to store its read-only programming. Each of the six modules hold 6K words of memory, each word being 15 data and one parity bit. The programs are 'stored' in the core rope during its construction when wires are woven either through or around the cores to permanently set the value of that bit to 1 or 0.

During development of the programming it would be too cumbersome to wait many weeks for the weaving of new core rope modules anytime a change is made to read only memory contents. Several methods were used to avoid the delay, by simulating the read-only core rope using some type of regular computer memory. One such method installed two Core Rope Simulator boxes into the AGC in lieu of the six core rope memory modules it normally uses.

The Core Rope Simulator box is connected by two thick cables to some ground-side racks of machinery. The simulator box will intercept the address and control signals that come from the AGC to the core rope modules, communicating those requests to the external system which in turn feeds the word of data that is associated with that address.

|

| One of the two 85 pin connectors on the core rope simulator boxes |

LTA-8 was the unit used to certify the follow-on LMs for use in space. LTA-8 was set in a large vacuum and thermal test chamber in Houston, where astronauts worked with the machine to ensure that the flighty-ready LMs were safe for human flight.

A core rope module implements the 6K words of 16 bits each using only 512 large cores in a module. Each core stores the data for 192 bits (12 words). It does this by weaving the wires for all 12 words through the single core if that bit is to be a 1, otherwise the wire is woven outside of the core ring.

|

| Connectors representing three of the core rope modules; these plug into the AGC |

When the control signal requests the reading of the content, the core ring is reset. Any wires that are woven through the center of the core ring will see a pulse as the core ring is rest, while the wires bypassing the core don't see any signal.

The strand number selects which of the 12 words of that core are to be channeled back to the sense amplifiers inside the AGC. Thus, the address and control signals are pulses that select and set cores, then reset them to cause the core to send pulses back to the sense amplifiers.

The core rope simulator boxes we are restoring do not have actual core rings, nor are they organized into six modules or 12 strands of words or 512 core ring addresses. The box has to interface with the same circuits that normally set, reset and select core rings, which it does by using small transformers that electrically act like the cores.

While the core rope modules are organized into six modules, 512 core rings, 12 strands and 16 bits to the sense amplifiers, the actual memory address inside the AGC is a linear range of 36K continguous word addresses. The external system connected to the core rope simulator boxes also sees a linear range of 36K contiguous word addresses, not modules, strands and cores.

Thus, the core rope simulator box accepts pulses from the AGC that would, in real core rope modules, set or reset a core ring at specific times. It has to save those module, strand and core addresses from the six sets of pins where the six real modules plug in. It will convert the addresses back to the linear range and send that address out to the external system.

The external system looks up the contents of the linear range address it received over the thick cable and sends that word back to the core rope simulator boxes. The box will then take the 16 bit value and use it to generate signal pulses via transformers that will look, to the sense amplifiers in the AGC, just like a pulse that was generated by a real core ring resetting.

We received the core rope simulator boxes with the AGC, but did not have any documentation at all about them. No schematics, no diagrams, no description of how they worked. Worse, we didn't have the ground based external system or the thick cables that run between external system and core rope simulator modules.

Ken had to reverse engineer the two boxes, understand their operation and build schematics. He then had to design and build an external system that would connect via thick cables and work properly with the simulator boxes. It had to recognize the linear address coming from the boxes, interact with the control signals at the right time, and feed the desired word of data back to the simulator boxes in time for them to pass the data into the AGC.

The external system is built around a Beaglebone and a custom printed circuit card, makes use of the same 85 pin aerospace connectors that are on the outside of the core rope simulator boxes, and will allow us to hold onboard all of the known versions of Apollo software, so that we can select which version is active to the AGC. For example, we can pick Luminary 210 which is the software that flew in the LM on Apollo 11.

No comments:

Post a Comment