CONTINUING TO WORK ON THE DRIVE ON THE BENCH

Here is my drive bench - the drive, multiple power supplies, and the oscilloscope to observe the operation of the disk drive circuitry.

EVIDENCE THAT THE RATE GENERATOR AND DETECTOR WORK PROPERLY

My scope captured a bit over 100 milliseconds of startup, where the ramp generator settled down, lowering the voltage below the threshold that triggers the set pulses for the 70 percent latch. The set line is steadily high, as it should be.

|

| Blue line is set pulse, green is ramp detector output |

This would turn off the squelch circuit to start the conversion of the index pulses into a voltage that represents the frequency of those pulses. At nominal speed, the integrator will generate about 5.5V if the pulses are arriving at the proper rate - one each 10 milliseconds - due to the drive rotating at 1500 RPM.

SQUELCH CIRCUIT IS MISBEHAVING EARLY, WOULD BE OKAY LATER

I see that the squelch output seems okay near the end of the spinup, as seen by the purple line in the first scope trace in this post. However, at the beginning it is not correct at all.

The yellow line is the integrator output, which should have been blocked by the squelch circuit until the drive is up to speed and the blue line attains a steady high level. The green line is the ramp detector output, still up at 5V. It will stay that way for more than 80 milliseconds before it begins dropping. The purple line is the squelch circuit output, low allowing the integrator to run while it slowly builds up to a logic high state.

It appears that the squelch does get up to the high level but does so too late to stop the integrator from zooming over the threshold. When the detector sees the integrator reach a target voltage, it stops resetting the 70 percent latch. Since the blue line is still emitting set pulses this early in the spinup, the latch will lock to the on state.

7235 IS A VERY DENSE SLT CARD AND CHALLENGING TO REVERSE ENGINEER

The card has seventeen SLT modules, seven discrete transistors, three discrete diodes, quite a few individual resistors and capacitors, plus many packs containing multiple resistors or RC networks. Many of the traces run under components on the top side, especially the SLT modules, so visual tracing doesn't work well.

Reverse engineering requires a lot of reference material, to understand the parts within each module type and the nature of all the resistor, capacitor or RC packs. The transistors are private labeled, meaning that their specifications can't be matched to commercially equivalent part numbers.

It would take many hours to decipher and draw out the schematics for the card. Instead of doing a wholesale recreation of the schematics, I will draw out what I need once I can laser focus on specific gates or areas of the design that are malfunctioning.

SQUELCH CIRCUIT SHOULD START OUT IN HIGH OUTPUT BUT DOESN'T

The intent of the speed detection circuits is to have the squelch producing a logic high until the ramp generator/detector has stabilized at full speed with a steady high output. Only then should the squelch go low. It is starting low. This may be due to a bad diode, capacitor or transistor that is pulling the output line down when it should not.

The squelch logic is extremely simple on paper - a single AND gate with inverted output (NAND in modern terminology), fed by one signal that goes high when the motor is running and another signal that goes high when our rate generator/detector achieves a steady state of logic high.

That is the point in time when the squelch line should drop to logic low state, freeing the integrator to be charged up by index pulses every 10 ms. Since the squelch out begins low, the integrator does its thing far too early. The ramp generator/detector took about 100 milliseconds to get to its steady state value, but the integrator is running in the first 10 milliseconds, when it should have waited.

Neither input to the AND gate is accessible by pins on the card - they are purely internal. Only the output pin B05 is accessible, making it hard to determine whether the gate is malfunctioning or one of the inputs is wonky.

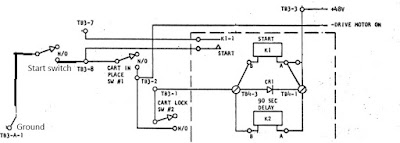

The motor running signal is produced by an inverter (NOT gate) which is wired to the motor start circuit. The signal going into the inverter is the 48V present through the Start solenoid, but to activate the solenoid our side of the coil is pulled to ground. This occurs through the start switch and a microswitch that indicates that a cartridge is in the drive. When I observed the input to the inverter, I saw a disturbing bounce up to 8V on the line, which will cause the inverter to output logic low.

The blue line is the 48V signal -Drive Motor On which is inverted then used in the NAND gate to combine with the steady set pulse level that will eventually be produced when the green line becomes a steady high signal. The yellow line is the integrator, running because the squelch isn't blocking it. The purple line is the output of the squelch NAND gate, extremely wrong and actually looking like the integrator output is shorting the squelch gate.

Just as troubling, when I look at the drive motor on signal in blue, it drops steeply to ground when the start switch is activated, as it should, but then climbs back up to about 8V which is far too high to be seem as a logic low input to the inverter.

The effective circuit for that signal is not complex. 48V flows through the motor relay, through a microswitch and then through a temporary SPST toggle switch I use to start the drive, finally to ground. In order to see 8V at this point, the resistance of the microswitch and toggle switch must be high enough to form a voltage divider with the effective resistance of the motor relay coil,

The switches and wire should be nearly zero but perhaps I need to burnish the contacts. Electrically, the resistance of the two switches to ground is in the ratio of 8 to 40 with the resistance of the motor relay coil - this produces 8/48 of the end voltage at the junction where we feed the inverter.

If we assume the relay coil consumes 5W, which is too high but for the sake of the analysis I picked a number that would draw a bit more than 100ma at 48V. That coil would present a resistance of 480 to 500 ohms at 48V to draw the 100ma current. It is more likely that the coil presents a resistance about five times as high and the current and power consumption would be five times as small.

To see an 8V voltage drop on the resistance between ground and the inverter input, assuming the 100ma current in the circuit, means that we have about 80 ohms of resistance between the -DC Motor On wire and the ground, passing through the two switches. Realistically if the current is indeed about five times smaller, typical of relays of this sort, then the resistance would be five times larger. That is an unexpectedly high level.

Another possibility is a defect in the card that is injecting this 8V from the input of the inverter. Our supply rails are 3 and 6V, thus this doesn't seem likely either.

No comments:

Post a Comment