I pulled out the spring that pulls the tab interposer rearward, since it was not exerting any force. Comparing it to the proper spring which is much shorter, the reason for its failure to work is obvious. I have the proper spring and have to get it attached using springhooks and other tools that I can snake through the very limited openings given me access to the interposer and the rear attachment point.

|

| Incorrect, overly long and weak spring on left, proper one on right |

That done, I tested the tab interposer which now snaps back cleanly when pulled down, which means it will work when I reattach the operational magnet assembly and all the pull links. Before I reassemble, there is another spring, the one that extends from a tang on the back of the backspace interposer and holds the backspace operational latch frontwards, out from under the operational bail.

It is only when the backspace interposer was triggered and slid rearward that it will push the backspace operational latch under the operational bail. The operational bail oscillates down and up with operational cycles, pulling down on any operational latches which are pushed under the edge of the bail when it moves. The bail pulling down on operational latches is coupled through pivots, levers and fulcrums to the various mechanisms to accomplish the movements such as space, backspace, tab, return and index.

I got the spring hooked over the backspace operational latch but now have to force it over the tang on the backspace interposer. A few tries with sets of springhooks failed, after which I took a breather from this somewhat frustrating task. When it is on, I can reattach the operational magnet assembly since I won't need the access to the interposers any more.

I managed to hook the spring on, but while I was moving the machine around to install the operational magnets, another of the damned springs between interposer tang and operational latches came loose. I packed it in for the night and will wrestle with all the springs tomorrow, then reinstall my operational magnet assembly.

SAC INTERFACE FOR ADDING PERIPHERALS TO THE 1130

It was a terrific battle but finally I got my enhancement cable made. I had to snake a stiff wire through, tape the twisted pairs around then end, and then pull it back through the 17 feet of heat shrink. It took a good 100 minutes to finally work the stiff wire through the tubing, since it was pushing a bendable wire not actually any pulling.

There was no way to wires pulled through the thinner (1/4") heatshrink tube which would have been a nice fit, so I had to use a 1/2" tube which would not have tightened enough to hug the five twisted pairs. I took some token ring cable and snaked it through as a stiffener and to eat up the spare space, then applied the heat gun to tighten up the cable cover.

The male plug is now attached to the cable and the other end is snaked into place inside the SAC Interface Box. I found a good spot to connect the female connector on the 1130, near where the other SAC cables are connected. Once I build the small daughter boards that will sit near the 1130 logic gates and interface the signals to my cable, I can make up the wiring to run inside the 1130 cabinet.

I settled on the design for the small card to be mounted inside the 1131 near the logic gates and began wiring it up (with an IC socket as I don't have the chip yet). Still a few details to work out, such as the mounting location and hardware.

I ordered a small board for the power supply which will be TTL level (+5V), whereas the 1130 uses +6, -6 and +3V supplies. The DC-DC converter board will tap onto the +6V supply of the 1130 and produce +5V for any and all circuitry I place inside the 1131. Initially, it will provide power for my emulation engine (implements a virtual Prog Load button) and for the daughter card for the interrupt levels.

I documented the pin assignments on the connector for the SAC Interface enhancement cable, so that I can wire up the 1130 side female connector and begin hooking the SAC Box wiring into the fpga. As soon as I have the console typewriter out of the way, I will open up the keyboard and upper cover of the 1131, to begin locating and attaching my boards and cables for the SAC enhancement.

I will secure the daughter board under the top cover, to the right of the console printer but still left of the usage meter and CE key. With the location set, I ran the twisted pairs that carry the interrupt level signals up to the daughter card from the IO connector panel at the bottom rear, having first housed the twisted pairs in the 1/4" heat shrink tubing.

Tomorrow, I will install the emulation engine and its relay board under the keyboard and switches panel, which will have its own run of twisted wire from the IO connector panel. With the wires in place, I will crimp all the female pins to the wires and install them in the female connector housing. That will get fastened with screws and nuts into an empty space on the IO connector panel.

I settled on the design for the small card to be mounted inside the 1131 near the logic gates and began wiring it up (with an IC socket as I don't have the chip yet). Still a few details to work out, such as the mounting location and hardware.

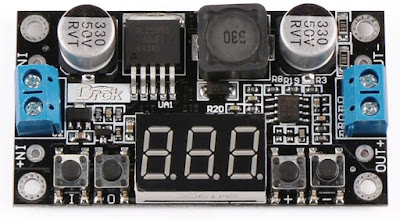

I ordered a small board for the power supply which will be TTL level (+5V), whereas the 1130 uses +6, -6 and +3V supplies. The DC-DC converter board will tap onto the +6V supply of the 1130 and produce +5V for any and all circuitry I place inside the 1131. Initially, it will provide power for my emulation engine (implements a virtual Prog Load button) and for the daughter card for the interrupt levels.

|

| DC - DC power supply to cover SLT +6V supply to +5V for my TTL logic |

I will secure the daughter board under the top cover, to the right of the console printer but still left of the usage meter and CE key. With the location set, I ran the twisted pairs that carry the interrupt level signals up to the daughter card from the IO connector panel at the bottom rear, having first housed the twisted pairs in the 1/4" heat shrink tubing.

Tomorrow, I will install the emulation engine and its relay board under the keyboard and switches panel, which will have its own run of twisted wire from the IO connector panel. With the wires in place, I will crimp all the female pins to the wires and install them in the female connector housing. That will get fastened with screws and nuts into an empty space on the IO connector panel.

No comments:

Post a Comment